Zemax OpticStudio

Purpose

-

Validate Optical Performance of Optical Ground Station (OGS) & Payload

-

Create Simulations representing optical layouts

-

Generate Tolerancing Data accounting for mechanical & thermal effects on optical misalignment

Overview

Ansys Zemax OpticStudio (Zemax) is an optical simulation software used as a preliminary validation analysis tool for the Optical Ground Station (OGS) & Payload. Zemax, combined with its Python ZOS-API for automated ray-tracing, more efficiently provides data on the geometric misalignments within the optical design, which also helps achieve a more precise understanding of how certain hypothesized physical phenomena are propagating through the optical system.

Some examples of acquired Zemax applications include: * Testing slight misalignments from lens vibrations * The thermal expansion of the CubeSat’s plating * Beam polarization conversion efficiency * Offset trajectories caused by the uplink beacon’s angular misalignment

This data is used to obtain thresholds for the PULSE-A laser-communications optical performance, which not only determines which products are most effective, but also how the sub-assembly designs should be refined to satisfy these thresholds.

Relevant Zemax Tools

-

Zemax can model the components relevant to the Optical Payload: sources (beams), lenses, mirrors, filters

-

Jones Matrices: used for analyzing polarization propagation through system (further research needed)

-

Sequential-Mode Analysis: Linear beam paths, but more comprehensive beam-profile analysis, polarization data, etc.

-

Considering deeper analysis of individual components along beam paths, e.g. Polarization through waveplates, more gaussian beam-profile data at QPD

-

-

Nonsequential-Mode Analysis: Optimal for complex beam paths → beam-splitting, multiple sources, scattering, stray light, etc.

-

CubeSat’s Optical Payload Design is best-tailored to Nonsequential modeling: 2 sources to analyze (OGS Uplink Beacon + Payload Downlink Transmission)

-

-

Coating Data Files: Method for defining customized transmittance/reflectance for nonsequential ray analysis

-

Useful for simulating products accurate to the product specifications: wavepass dichroics & bandpass filters

-

-

Ray-tracing: Zemax’s method for analyzing detector data (e.g. QPD)

-

Nonsequential-Mode: exclusively Irradiance Maps

-

-

ZOS-API + Python: Interacting with Zemax’s User Interface without the GUI → Better Automation

-

Powerful Tool for Tolerancing Data across various parameter values (e.g. tilt angles, component positions, component sizes, etc.)

-

-

Well-documented Public Resources:

-

Zemax Knowledge Base: Main hub for Zemax Tutorials

-

Zemax Community Forum: Site to ask questions about specific Zemax issues

-

Zemax also provides many test examples that apply useful features (e.g. ZOS-API Connection examples, approaches to model gaussian sources)

-

Zemax Simulation Procedure

-

Identify theoretical concerns with the optical system (e.g. vibration, thermal, body-pointing, etc.)

-

Research Zemax’s available tools for analyzing the problem (e.g. ray-tracing, coating, irradiance maps, sequential vs. non-sequential modes, ZOS-API, etc.)

-

Identify available data types that Zemax can output (e.g. power, centroid, irradiance, etc.)

-

Determine characterization of optical performance (Data on QPD/Detectors)

-

Develop algorithm for ray-tracing & tweaking parameters (ZOS-API Python)

-

Collect relevant data & analyze tolerancing results

Simulation Results

-

Accurate, Non-trivial Model of Payload Optical Layout

-

Capable of Non-sequential 3D Layout

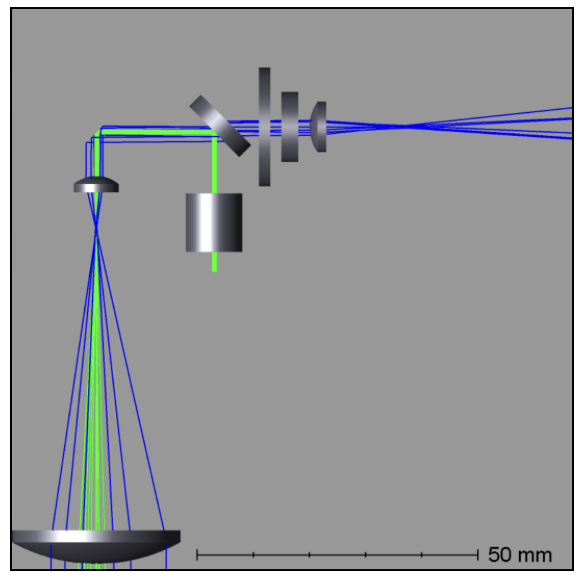

Current Payload Optical Layout * Blue beams represent part of the OGS Uplink Beacon (1064nm); Green beams represent part of the Payload Downlink Transmission (1550nm).

The Transmission assembly encodes and modulates (at 1–10 MHz) the data into a circularly-polarized, amplified beam for the OGS to receive and decode. The transmission beam follows the same optical path as the uplink beacon, and requires a dichroic beam-splitter to multiplex the two signals.

Use of Irradiance Maps

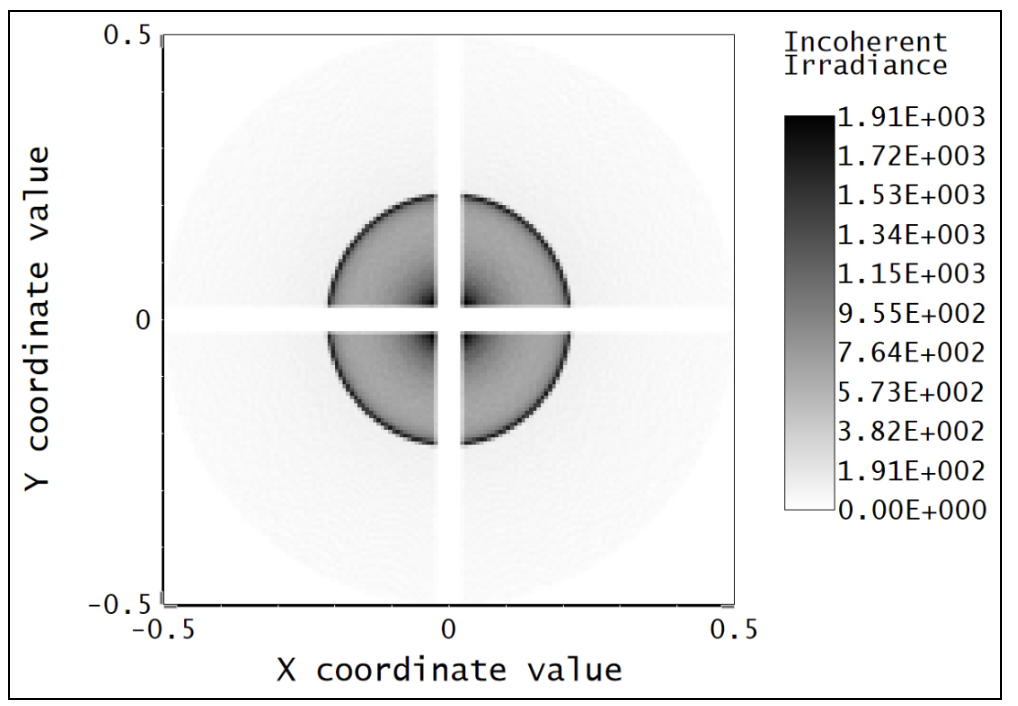

Irradiance Map of OGS-Beacon Power Distribution on QPD Detector

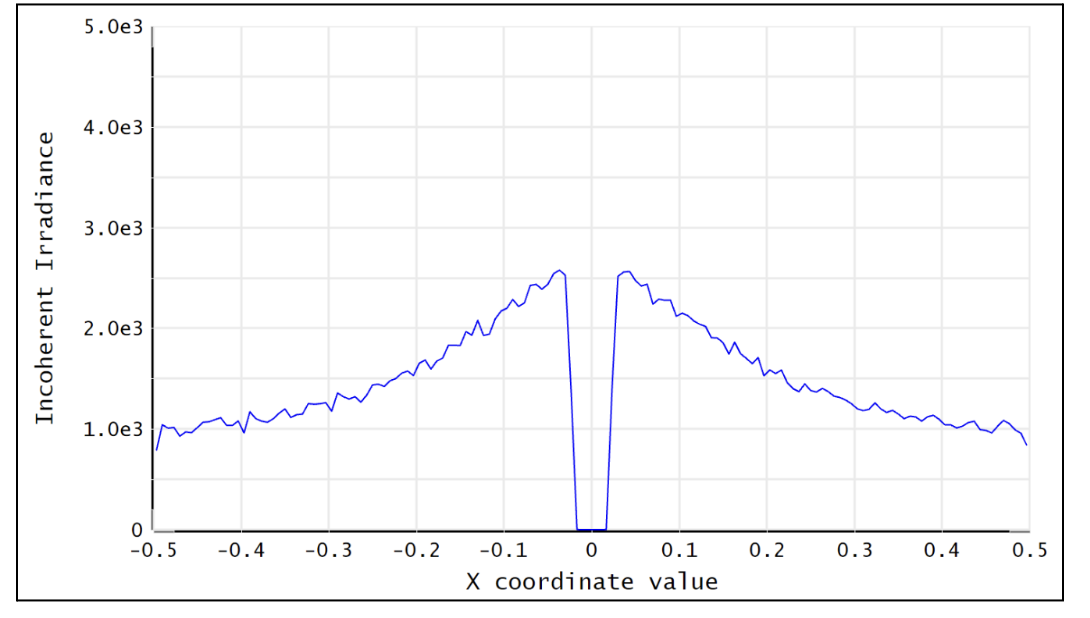

Near-Center Gaussian QPD Irradiance Profile Plot_

Note: the gaps between the gaussian distribution represent dead-zones of the QPD (between each quadrant). Darker (more irradiant) circumference & halo hypothesized to be caused by lens spherical aberrations.

The Payload uses a 2x2 Quadrant Photodiode (QPD) with 1mm active diameter. The size constraints of such a detector require extremely precise pointing & focusing from other Payload assemblies. Slight misalignments throughout the system result in non-uniform voltage signals.

ZOS-API in Python

Automates interaction with Zemax OpticStudio’s user interface (replaces GUI) via Namespaces (OOP). Iterative ray-tracing opens up tolerancing over multiple parameter values for a single/multiple optical components.

FSM Mirror Preliminary Requirements Determination

The FSM corrects uplink beacon misalignments caused by body-pointing, thermal drift, or vibrations. For angular errors up to 1.00°, the FSM adjusts the optical path to center the beam on the quadrant photodiode (QPD).

Predicted FSM Mirror Requirements from Zemax Simulations

| Specification | Requirement | Justification |

|---|---|---|

Mechanical Angle (deg.) |

≥ ~4.1° |

Capacity for overcorrecting from 1.00° Body-Pointing Error ensures that the optimal FSM Tilt angle is within the maximum mechanical FSM Tilt range. |

Active Diameter (mm) |

≥ 5.00mm |

Help to prevent vignetting along the edges of the FSM Mirror to collect the entire uplink beacon. |

Payload Body-Pointing Angular Misalignment Threshold for Fixed FSM Max Tilt Angle

| Specifications: | Requirement: | Justification: |

|---|---|---|

Mechanical Angle (deg.) |

≥ ~4.1° |

Capacity for overcorrecting from 1.00° Body-Pointing Error ensures that the optimal FSM Tilt angle is within the maximum mechanical FSM Tilt range. |

Active Diameter (mm) |

≥ 5.00mm |

Help to prevent vignetting along the edges of the FSM Mirror to collect the entire uplink beacon. |

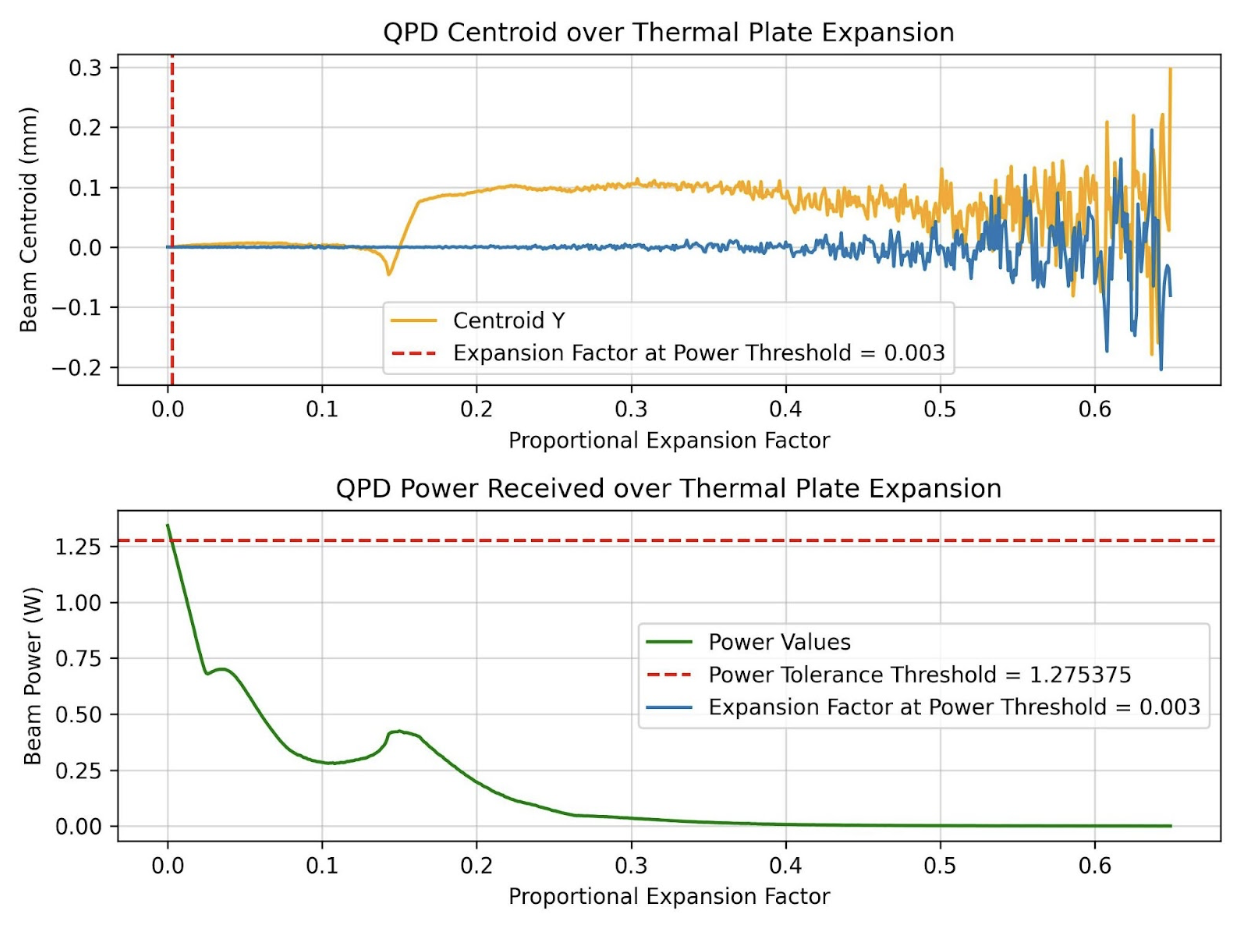

Preliminary Validation of Thermal Model: Plate Expansion

Assuming Uniform Expansion of CubeSat Aluminum Plating. We expect there to be misalignments due to thermal expansion of the plates.

Plots of Received Centroid & Power on QPD Over a Proportional Expansion Factor of Plating (from Zemax)

Note: Inconsistent Centroid Behavior observed starting from expansion factor of 0.4. Power threshold is a more sensitive characterization than the centroid.

Preliminary Validation of Back-Reflected Light

Optical components have imperfect transmission from ideal trajectory, and can reflect light backward through the optical layout.

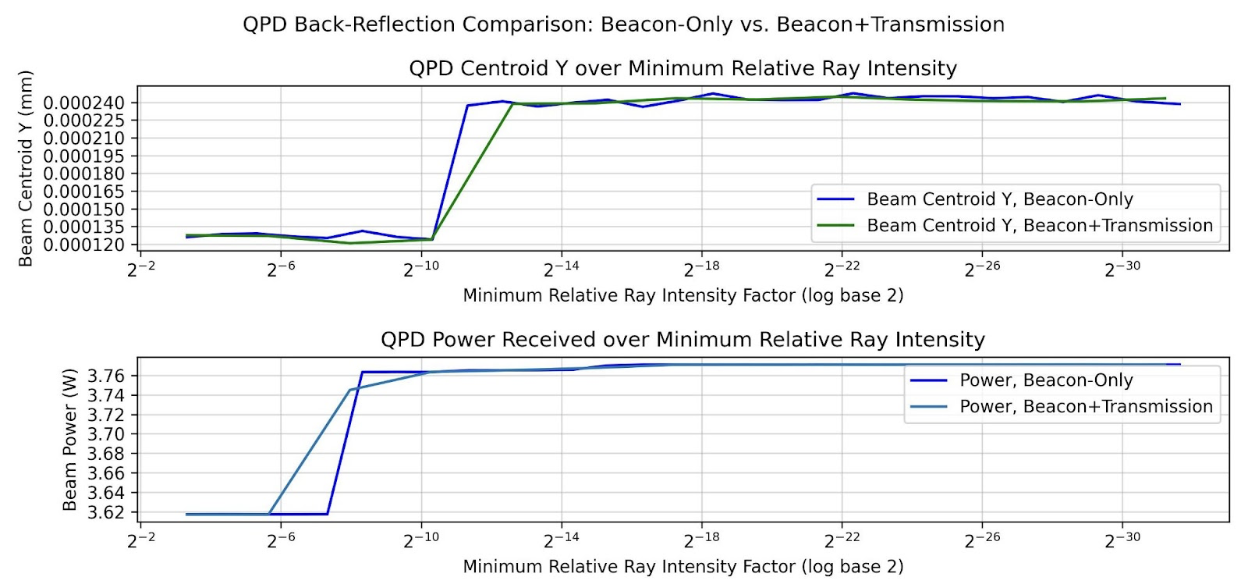

Plots of Received Centroid & Total Power on QPD Over Minimum Relative Ray Intensity (MRRI)

-

Minimum Relative Ray Intensity: Input as a scaling factor with respect to the incoming intensity of a bundle through an optical component, “Minimum Relative Ray Intensity” is defined as the minimum intensity of a back-reflected bundle that will be considered in the Zemax ray-trace analysis (e.g.: 2-6 x incoming intensity)

-

Consider rays both from OGS beacon & Payload transmission: Not easily distinguishable from OGS-beacon-only data. Centroid remains as an unconcerning factor; spike around 2-10 still is 3 orders of magnitude below the order of the QPD radius (0.5mm)

-

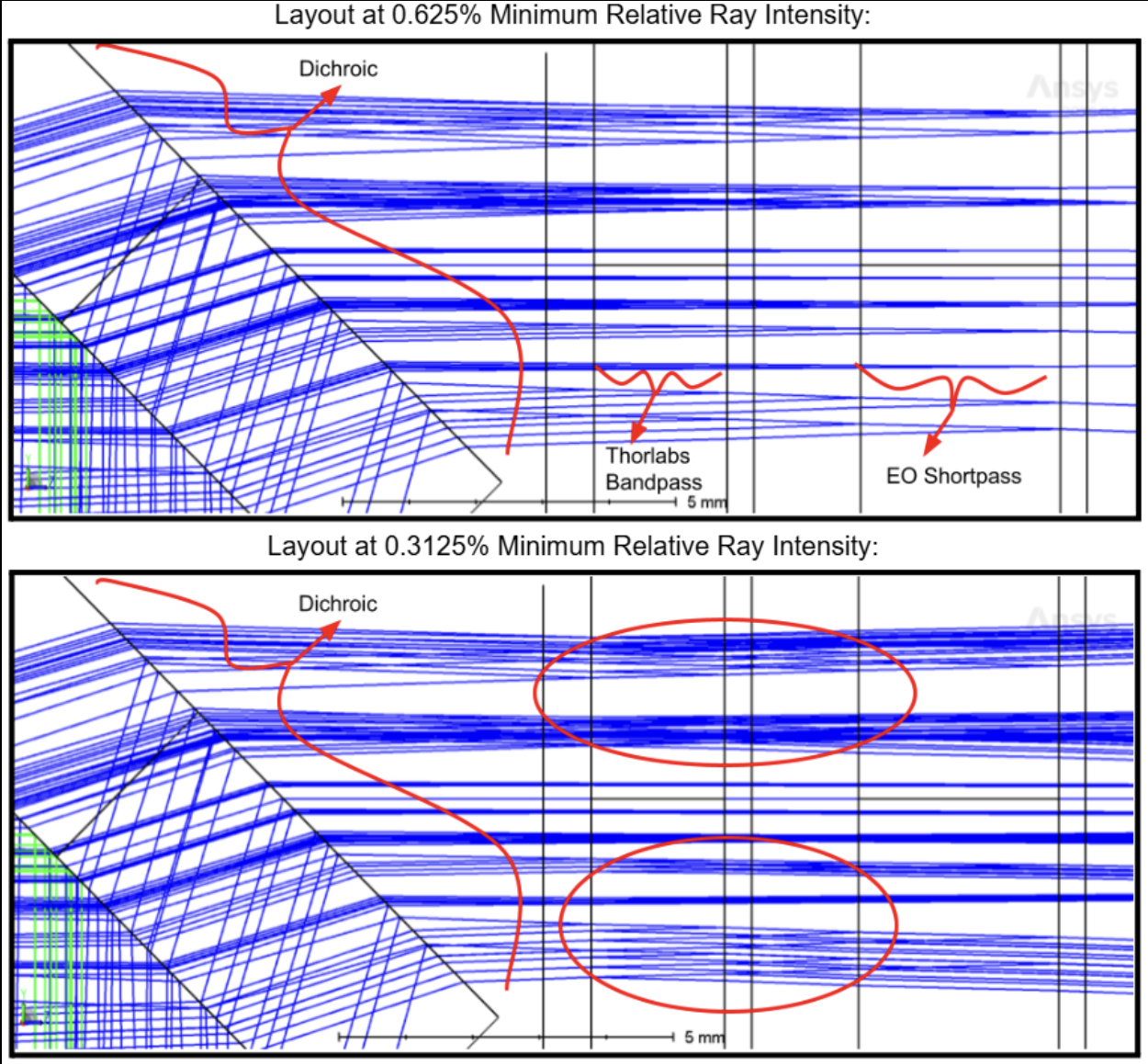

Power: 4.04% power spike around MRRI factor of 0.003125. We hypothesized to originate from Detection Subassembly’s filter stack:

Power Values through Optical Components (Uplink Beacon)

| Max Body-Pointing Tolerance (°, deg.): | FSM Max Tilt Angle (°, deg.): | Final Centroid pos. (+ overcorrection) (mm): |

|---|---|---|

0% |

1.109 |

0.0 + 0.00069201 |

5% |

1.056 |

0.0 + 0.00071147 |

Sample Rays Propagating through DS Filter Stack under different MRRI values (%)_

Understanding power losses through optical system: * Concerning the Payload link budget, how much power is being received at the QPD, and what causes the power losses? * Power Losses are more relevant to calculate as percentages (applicable to any product)

Power Values through Optical Components (Transmission)

| Component Name | Beacon Loss from Total (%) | Beacon Loss from Previous Component (%) |

|---|---|---|

Kepl. Telescope Aperture (Initial) |

0.0 |

0.0 |

Kepl. Telescope 30mm Lens (EO #45-241) |

0.49498 |

0.49498 |

Kepl. Telescope 9mm Lens (EO #28-952) |

0.90462 |

0.41168 |

FSM Mirror (Mirrorcle 6.4mm) |

2.2843 |

1.3923 |

SWP Dichroic (Thorlabs DMSP 1180T) |

8.665 |

6.5298 |

Bandpass Filter (Thorlabs FLH1064-8) |

23.756 |

16.523 |

Shortpass Filter (EO #89-671) |

36.862 |

17.189 |

QPD Focus Lens (EO #49-876) |

61.807 |

39.509 |

Impact

-

Develop Preliminary Prototype for entire Payload Optical Layout (that is not currently feasible for physical lab validation)

-

Helped determine some relevant Payload FSM requirements: Minimum Diameter & Maximum Actuator Tilt Angle

-

Determined requirement for ADCS satellite alignment

-

Preliminary Validation of Current Payload Design for thermal & back-reflection tolerances

Next Steps

-

Develop Model in Sequential Mode: more comprehensive ray-trace analysis (More Gaussian Beam Data, Polarization Data, etc.), at the cost of less complex optical paths

-

Perform Vibrational Testing

-

Observe Polarization Data through System

-

Test Mirror Slew-Rate/FSM-QPD Feedback Loop through ZOS-API Python

-

Obtain more data on body-pointing misalignment vs. Required FSM Tilt vs. QPD Power Distribution to develop an electronic voltage-transfer function